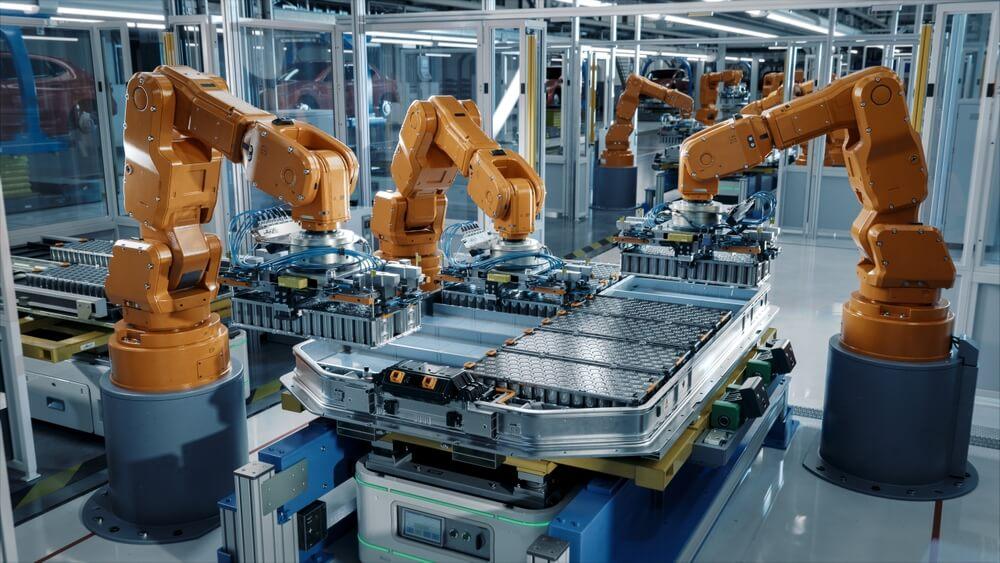

A summary of how conzura enabled an industrial automation customer to scale IoT-driven control systems, robotics engineering, PLC development, and real-time embedded platforms for next-generation manufacturing.

The customer required multi-disciplinary engineers capable of designing IoT-based control systems, robotics applications, PLC and SCADA programming, real-time embedded architectures, and industrial communication protocols. Sourcing specialists with deep technical expertise across automation frameworks was a challenge.

conzura assembled a diverse engineering team skilled in industrial IoT, embedded C/C++, RTOS, robotics platforms, PLC/SCADA systems, and communication protocols such as CAN, SPI, UART, and Modbus. Engineers supported full-cycle automation development—from system architecture to integration and testing—enabling improved efficiency and readiness for next-gen manufacturing.

The engagement improved automation reliability, accelerated delivery of robotics and control systems, and strengthened the customer’s ability to deploy smart manufacturing solutions. Engineering cycles became faster, more predictable, and fully aligned with Industry 4.0 transformation goals.